(My FLW interpretation)

Wednesday, December 9, 2015

Sketchbook

This is one of my first sketches of the year.. This was drawn in Langford C

I drew this on my dinner break when I worked at Smoothie King at the Rec on campus.

This was another sketch I drew on my break while working at Smoothie King. I went up the stairs and drew the top of the indoor rock wall. I found the perspective to be challenging.

This was a doodle during a meeting.

This was a concept during that meeting. I wanted a pod door to be this mystical winged door that slides back and up in a sleek fashion. I was shot down and mocked for a few months.. #noragrets

This is the Aerospace Building around sunset.

Column on the Administration Building

Lamp inside the MSC flagroom.

Sketch series of the Student Transit

Saturday, December 5, 2015

Book Review: The Devil In The White City- Murder, Magic, and Madness at the Fair that Changed America by Erik Larson

Discovering the Book

Book Up Until the Chapter "Acquiring Minnie"

Concluding Thoughts

Discovering the Book

I first learned of the existence of this non-fiction novel after conversing with my perceptive aunt on my preference of non-fiction novels. She told me about this book called the "Devil in The White City," and about the protagonist being an architect in charge of the Chicago World's Columbian Exposition, 1893, and the antagonist being a serial killer, and how the lives of the two public names intertwine, yet they never meet.

Book Up Until the Chapter "Acquiring Minnie"

Introduction

In the beginning, the book introduces the two men in brief with two quotes.

Daniel H Burnham: Make no little plans; they have no magic to stir men's blood.

Dr. H. H. Holmes: I was born with the devil in me. I could not help the fact that I was a murderer, no more than the poet can help the inspiration to sing.

Now I would like to highlight in a bulleted list of all the interesting facts of American history that I learned reading this book:

- Daniel Burnham's and John Root's firm, downtown Chicago had a gym. One of the first, to pioneer bringing exercise into the office

- The fair was almost held in New York, and the pack of New York were hesitant to contribute drawings until Burnham convinced Richard Hunt, an alpha in a sense, agreed- the rest followed (George B. Post and Charles McKim)

- Chicago's soil is wet, and dynamic, making setting a foundation a challenge every time. Also, the building season ceased for the winter.

- Chicago reversed the flow of the river. A great engineering feature.

- Frederick Law Olmstead, pioneer of landscape architecture, designed Central Park in New York, and the simple elegant ground of the fair.

- Jack the Ripper killed about a dozen prostitutes, while Dr. H. H. Holmes killed thousands.

- Burnham, at least at first, cared for the employees. The construction workers of the world's fair were housed and fed.

- The fair was a giant economic opportunity, so many young men and women fled to Chicago. Men got blue collar jobs building the buildings in the fair. (and when there was a layoff, many of the men became homeless- which is believed to be when the term "hobo" was first coined). Women worked as receptionists- unless they fell of into the trickery charm of Holmes that led them to their tortured deaths.

- The medical schools, such as the University of Louisville, were in short supply of bodies and were desperate. "They attempted to rob a grave at the State Asylum for the Insane in Anchorage, Kentucky, this time on behalf of the University of Louisville. "Yes, the party was sent out by us," a senior school official said. "We must have bodies, and if the State won't give them to us we must steal them. The winter classes were large and used up so many subjects that there are none for the spring classes." He saw no need to apologize. "The Asylum Cemetery has been robbed for years," he said, " and I doubt if there is a corpse in it. I tell you we must have bodies. You cannot make doctors without them, and the public must understand it. If we can't get them anyother way we will arm the students with Winchester rifles and send them to protect the body snatchers on their raids.""" pg. 150-51

- This was Holmes target market. Medical schools paid a lot of money for bones, so Holmes was a frequent supplier.

- There were many disasters, and disbelieve of the fairs success

- including a failure to include a live load for the glass ceiling due to harsh winter conditions

- The goal of the fair was to out "Eiffel" Eiffel's Eiffel Tower

- Which they did with the first giant Ferris wheel designed by an engineer with many connections, George Washington Ferris.

- Walt Disney's dad was a craftsmen and contributed to the fair.

- Daniel Burnham was slowed down by all of the committees, subcommittees, and the fact that he had to share power

- In another article I read about the Hyperloop, HTT technology CEO, Ahlborn made a similar comment.

Concluding Thoughts

This book is jammed pack of interesting facts. I would recommend for any architecture student who enjoys history, and a bit of mystery.

Rapid Prototype

3D Printing Background

3D Printing Background

Personal Experience with 3D Printing

The Lessons Learned

The Lessons Learned

3D Printing Background

Rapid prototyping began as early as 1992. A stereo-lithographic apparatus machine (SLA). This technology has continued to develop throughout the decade, enabling seemingly impossible circumstances a reality. There are many types of 3D printers that range in price from $100 to if you have to ask, then you can't afford it. The most common type of 3D printer you can find on campus is Makerbot, which uses a reel of a plastic (PLA). The design possibilities are endless.

That leads to another great question, just because it CAN be printed, should it be?

That leads to another great question, just because it CAN be printed, should it be?

Personal Experience with 3D Printing

A team of two, myself and a classmate, designed a parametric wall to metaphorically represent the climate in Texas during the years 1970, 1980, 2006, and 2007. We would construct a hollow core door to a dolly and then build a grid with a series of dowel rods at varying lengths, then attach a series of 3D printed nodes to the end to seal the corners of recycled cardboard pieces we laser cut into varied sized triangles. Excuse the run on, but the final product should have looked like a black sleek wall. My team printed nodes for my project on three attempts. The first set, were much too small. We learned that in order to take a 3D model, in any given software program capable of exporting into an .stl file, you have to apply a mesh to it, so the printer will recognize it as a solid. We then decided to go ahead and outsource the second print to the EIC. Given that they are engineers, they are surely they will get it right on the first try, and they did. We also gave ITS a second chance, and they got it right too.

The Lessons Learned

Through this project, I learned how to apply a pattern to a parametric surface using Revit software.

I conceptualized the building process, and how the 3D printed nodes would attach to each of the dowel rods. However, more of the lessons I learned derived from mistakes-which should be of no surprise. As of now, we have two correct batches of prints, but none of them are labeled. Because each node is different, not labeled, it is an absolute headache to assemble. Going forward, I would assume the role of project manager, and demand more communication, and responsibility in my team. I would label everything to a point where it would appear redundant, maybe write an instruction manual on how to assemble a wall. This way, an outsider would be able to come in, and be able to assemble the wall without having to know everything about the project. I would even consider printing modular pieces for another application, such as a sun shade for the exterior of a building.

The Lessons Learned

Through this project, I learned how to apply a pattern to a parametric surface using Revit software.

I conceptualized the building process, and how the 3D printed nodes would attach to each of the dowel rods. However, more of the lessons I learned derived from mistakes-which should be of no surprise. As of now, we have two correct batches of prints, but none of them are labeled. Because each node is different, not labeled, it is an absolute headache to assemble. Going forward, I would assume the role of project manager, and demand more communication, and responsibility in my team. I would label everything to a point where it would appear redundant, maybe write an instruction manual on how to assemble a wall. This way, an outsider would be able to come in, and be able to assemble the wall without having to know everything about the project. I would even consider printing modular pieces for another application, such as a sun shade for the exterior of a building.

Saturday, November 28, 2015

HyperWhoop

This summer I learned of a competition hosted by SpaceX, after following Elon Musk and all of his businesses.

So I formed a team.

Iyabo, Bri, Ken, Jaime, and Sergio. We met and worked all summer, developing potential design solutions for the vague first edition of competition rules.

We lost Bri and Jaime in the fall to study abroad programs. Sergio quit. And because Ken signed up to take the Hyperloop class for his capstone engineering class, he was unable to still be on our team. Things were looking down, except for the fact that Dr. Culp had agreed to be our faculty adviser.

The EIC hosted a "Hyperloop Kick-Off Meeting"

There, Iyabo and I met another team, HyperWhoop. We decided to merge, as well as pick up a handful of students who were interested in the competition, but did not have teams.

HyperWhoop, composed of less than twenty students, has met every week, three times a week, with hopes of making it to design weekend, and actually building a pod to test. We have a propulsion team that meets on Mondays, a structures team that meets on Wenesdays, and an overall team meeting on Thursday when we get an hour of Dr. Culp's time before he rushes off for date night.

After several delayed release dates, and deadlines, on Wednesday, November 25th, at approximately 4:35, I found out we have made it to design weekend. Dancing memes and ecstatic comments blew up the hyperloop crew's group me. We could not have done this without the dedication of the entire team, the organization and leadership of Katie, and the direction of Dr. Culp.

For the part, we will be given a mentor, sponsors, and a prestigious pitch coach. Two of our members will be training with him up until design weekend in January.

Unfortunately, I leave for Spain at the beginning of the year, and the design weekend, that is hosted at Texas A&M, isn't for another two weeks after I leave. I have requested that I still train with the coach, because it's free and I love learning. My team has agreed to skype me in during the event.

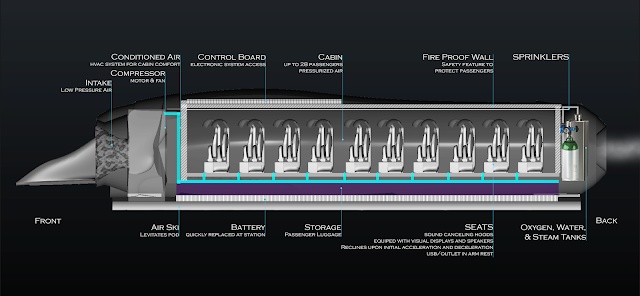

This is the side section I worked on for the competition.

So I formed a team.

Iyabo, Bri, Ken, Jaime, and Sergio. We met and worked all summer, developing potential design solutions for the vague first edition of competition rules.

We lost Bri and Jaime in the fall to study abroad programs. Sergio quit. And because Ken signed up to take the Hyperloop class for his capstone engineering class, he was unable to still be on our team. Things were looking down, except for the fact that Dr. Culp had agreed to be our faculty adviser.

The EIC hosted a "Hyperloop Kick-Off Meeting"

There, Iyabo and I met another team, HyperWhoop. We decided to merge, as well as pick up a handful of students who were interested in the competition, but did not have teams.

HyperWhoop, composed of less than twenty students, has met every week, three times a week, with hopes of making it to design weekend, and actually building a pod to test. We have a propulsion team that meets on Mondays, a structures team that meets on Wenesdays, and an overall team meeting on Thursday when we get an hour of Dr. Culp's time before he rushes off for date night.

After several delayed release dates, and deadlines, on Wednesday, November 25th, at approximately 4:35, I found out we have made it to design weekend. Dancing memes and ecstatic comments blew up the hyperloop crew's group me. We could not have done this without the dedication of the entire team, the organization and leadership of Katie, and the direction of Dr. Culp.

For the part, we will be given a mentor, sponsors, and a prestigious pitch coach. Two of our members will be training with him up until design weekend in January.

Unfortunately, I leave for Spain at the beginning of the year, and the design weekend, that is hosted at Texas A&M, isn't for another two weeks after I leave. I have requested that I still train with the coach, because it's free and I love learning. My team has agreed to skype me in during the event.

This is the side section I worked on for the competition.

ARCH 205 with Mark Clayton

Blogs & Drawings

Mass Manufacturing

Climate Panels

Villa Rotunda & Townhouse

Construction Model

Essay

Blogs & Drawings

Each week we are required to post one blog, and one drawing.

Mass Manufacturing

The class divided into assembly teams in the wood shop. The end goal, between the morning and afternoon studios, was to attach a hollow core door to a base with a trim on a dolly, to support parametric sculptures to be used over and over again. This process took about three weeks, about two weeks longer than it should have.

Climate Panels

After all of the doors were assembled, the class paired up to tackle the next project. The class analyzed data from 1980 to 2013. My team, Alpha, Panel 1, had the years 1980, 2007, 1970, and 2006. We looked at the highs and the lows of 4 evenly spaced times of the year. We then applied the climate data to a parametric curved surface.

Villa Rotunda & Townhouse

Next project, was to design a Villa Rotunda out by Mesina Hof in Bryan, and a Townhouse downtown Bryan by forming a firm of four. We were forced to merge our two person panel team with another team. Our communication has been sub par, and I am concerned for the continuity in the designs of our firm. We also have to build a massing model of each of these.

Construction Model

I have not even started this. I feel like drowning when I think about it too.

Essay

I am required to write an essay on Palladian architecture.

Fortunately, back when I was a sophomore, and in honors, I wrote an essay on this topic. Hopefully I can recover it in time, and just have it revised at the campus writing center. If not, please pray for me.

Mass Manufacturing

Climate Panels

Villa Rotunda & Townhouse

Construction Model

Essay

Blogs & Drawings

Each week we are required to post one blog, and one drawing.

Mass Manufacturing

The class divided into assembly teams in the wood shop. The end goal, between the morning and afternoon studios, was to attach a hollow core door to a base with a trim on a dolly, to support parametric sculptures to be used over and over again. This process took about three weeks, about two weeks longer than it should have.

Climate Panels

After all of the doors were assembled, the class paired up to tackle the next project. The class analyzed data from 1980 to 2013. My team, Alpha, Panel 1, had the years 1980, 2007, 1970, and 2006. We looked at the highs and the lows of 4 evenly spaced times of the year. We then applied the climate data to a parametric curved surface.

Villa Rotunda & Townhouse

Next project, was to design a Villa Rotunda out by Mesina Hof in Bryan, and a Townhouse downtown Bryan by forming a firm of four. We were forced to merge our two person panel team with another team. Our communication has been sub par, and I am concerned for the continuity in the designs of our firm. We also have to build a massing model of each of these.

Construction Model

I have not even started this. I feel like drowning when I think about it too.

Essay

I am required to write an essay on Palladian architecture.

Fortunately, back when I was a sophomore, and in honors, I wrote an essay on this topic. Hopefully I can recover it in time, and just have it revised at the campus writing center. If not, please pray for me.

Aggies Invent

OutlineDiscoveryParticipation 1: Internet of ThingsParticipation 2: Conflict and DevelopmentParticipation 3: Pediatrics(Work Environment)

DiscoveryI learned of this event through an acquaintance in an organization I joined junior year. Adway, an electrical engineering major, inquired my interest in an event called Aggies Invent. Within ten minutes, I had successfully completed my application for the program. A few days later I received an email from Mr. Boehm, congratulating me on my acceptance and attached was a detailed schedule of the upcoming weekend, a list of need statements, and directions on where to find the building.Every time I participate, it's a new team same duration of time. In 48 hours, you form a team of four to six people, take the need statement concept and bring it into fruition. Typically you spend all day Saturday designing, and Sunday is the presentation.

Participation 1: Internet of Things

Growing up, I had access to the outdoors, basketballs, volleyballs, cameras, and a limited amount of art supplies. This was the first time I was exposed to "grown up toys". My kind teammates did their best to dumb down the technical jargon for me. However, it is impossible to learn such technical detail in a weekend. I had a strong team, composed of two graduate students, engineers.. and then me. I pestered them as they programmed the xbee microcontroller. Adway, my friend, programmed an android app, while Chris and Mike worked on programming blinds to open upon command. Jake worked on the solar panel pv cell. JC worked on a fantastic video (which they like to use as an example of what to do in other Invent weekends). I worked on the graphics to describe the technical process in a beautiful way, and the powerpoint. Side StoryI built the window sill for the blinds to hang on out in the open lab space. This was my first time building a box, but I knew I was capable of it. One of the other team mentors made a comment, "Who gave the girl a drill" as I was assembling.. I was utterly offended. It never occurred to me that I was working in a "man's" environment. From that moment on, I have only wished to prove that women are just as capable of doing ANYTHING a man can do, with few exceptions. Sexist comments needs to stop.Blind Sided, app controlled solar panel blinds, was able to successfully prove their concept. We placed third, winning $500, divided six ways.

(app interface with working dial)

Most of the needs statements were focused around the Shea Butter process and economically empowering women in Africa. I was on a team of 5 members, and we decided to tackle and innovate upon the drying process of the Shea Kernels which is the 7th step in the entire process.I found this Aggies Invent to be most challenging to create a working prototype to prove our concept because the process alone takes a week, and we only had 48 hours.. We decided to innovate upon the actual drier. The women currently dry the nuts on racks within a mud bed.My idea was to have a fan to be implemented to circulate the air in between the racks, which will be powered by bicycles. I feel that incorporating bicycles into manufacturing, you humanize the manufacturing process, while allowing employees/workers to sustain a healthy lifestyle through exercise. I wanted to focus on this bicycle aspect, the simple mechanics of having the uniformed bike be placed on a stand, strapped to a belt, turn a fan, generate a current within the plastic covered bed, in a simple and inexpensive attempt to dehumidify the interior of the bed. Due to internal disputes on what the team should focus on, my idea was overlooked. We ended up 3D printing a box, and small scale modeling the design given to us in a research paper. To say the least, there was more conflict than development.Although we did not win, I learned a few video editing techniques, utilized my photoshop skills, and learned a lot about the Shea butter process in Africa and women empowerment.

Participation 3: PediatricsI know close to nothing about medicine. I had to have a blank google page just to process the need statements. I did not know my team until I raised my hand for the need statement listed above. Google, marvelous wonderful Google, provided me with quick and accurate information for all of my many inquiries. I did more research than designing, to fully understand the problem.

My team-

Carly: Freshmen General Engineer

Carly: Freshmen General Engineer

Brandon: First Year Medical School

Ryan: Freshman Business

Dr. Ken Brady

Margret: Junior Systems Engineer

Margret: Junior Systems Engineer

Vanella: Freshmen General EngineerJess: Junior Environmental Design

Abdul: Mentor

We worked together. Made every decision as

a team (which took a lot of time when there was disagreements). We decided to

focus on an operating table.

The Problem-There is limited surface area on premature babies, and applying sticky leads takes up too much space.The Solution-Weave electrodes into a fabric sheet, to be placed on top of a pressure sensor to give coordinates and activate appropriate electrodes to accurately get an ekg reading.

Our Product-

Market Validation-We were able to communicate with two doctors, both supporting this innovation for the operating room.

We are planning on starting a business with this product. (Tapping into a 6.9 billion dollar market might help pay off my ever growing student loans.)

(Work Environment)Instead of staying at home and watching Netflix with a bottle of wine, or going out to the clubs and getting "turnt" like a lot of my snapchat friends, I chose to spend 3 weekends creative problem solving, learning how to deal with different personality traits from engineer-types to business-minded individuals to students pursuing professions in medicine. I am beyond blessed for them allowing me into a program, three times! After the second event, they offered me employment in the engineering innovation center facility. Where I will continue to learn, and be surrounded by people much more intelligent than I. This may intimidate some, but this means I have nothing but knowledge to gain. I can not wait for the future projects I am brought onto the team, because of the experience I have gained while being associated with this facility. I am thankful every day.

Tuesday, November 17, 2015

Frank Lloyd Wright Home and Studio

Frank Lloyd Wright

With no doubt in my mind, would I have detested the existence of this man if I had ever the displeasure of meeting him. He was 5 foot nothing with an ego bigger than Kim and Kayne combined. However, there is no questioning the remarkable spaces he created.

After touring his home, and studio, I don't think that I would live in any of the spaces. I would like to talk about a few architectural elements that I admire about his design style.

-The front square entrance of his home had Greek entablatures lining the ceiling.

-The use of open space. Each room was defined by walls, yet seemlessly flowed into one another.

-He may have viewed people as a nuisance just standing taking up space, so to get them out of the way, the window seats were invented. I love the window seats! The ones in the children's play room may have been my favorite, because when you are sitting down, and look up, he cut a hole in the eave so the children could have a direct view of the sky. This is one way, Wright was able to connect with nature.

-He designed for nature into his house. During an expansion to connect the home to his studio, existed a tree, so he literally built around the tree. This was not the smartest decision because it caused problems down the line, but it is an interesting concept.

-Fun fact, one of his sons invented Lincoln logs.

-In his studio, adjacent to his home, on the facade facing the nosiest street, he placed Styrofoam columns. He was never an engineer, but this somehow eliminated the sound from the busy street and made it quiet inside the studio.

With no doubt in my mind, would I have detested the existence of this man if I had ever the displeasure of meeting him. He was 5 foot nothing with an ego bigger than Kim and Kayne combined. However, there is no questioning the remarkable spaces he created.

After touring his home, and studio, I don't think that I would live in any of the spaces. I would like to talk about a few architectural elements that I admire about his design style.

-The front square entrance of his home had Greek entablatures lining the ceiling.

-The use of open space. Each room was defined by walls, yet seemlessly flowed into one another.

-He may have viewed people as a nuisance just standing taking up space, so to get them out of the way, the window seats were invented. I love the window seats! The ones in the children's play room may have been my favorite, because when you are sitting down, and look up, he cut a hole in the eave so the children could have a direct view of the sky. This is one way, Wright was able to connect with nature.

-He designed for nature into his house. During an expansion to connect the home to his studio, existed a tree, so he literally built around the tree. This was not the smartest decision because it caused problems down the line, but it is an interesting concept.

-Fun fact, one of his sons invented Lincoln logs.

-In his studio, adjacent to his home, on the facade facing the nosiest street, he placed Styrofoam columns. He was never an engineer, but this somehow eliminated the sound from the busy street and made it quiet inside the studio.

Subscribe to:

Comments (Atom)